Of that growth 60 will come from the asia pacific apac region.

Restrike operation in sheet metal.

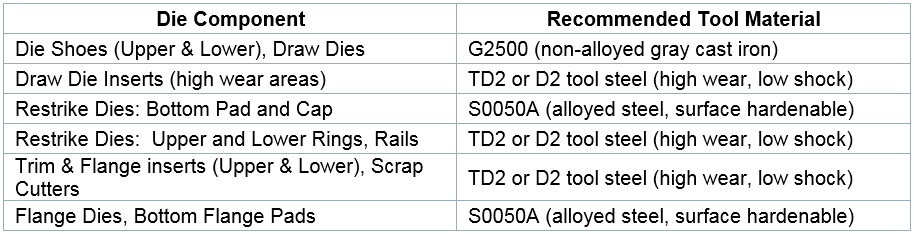

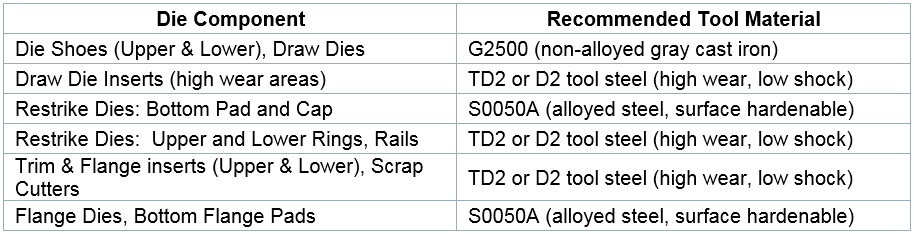

Generally press tools are categorized by the types of operation performed using the tool such as blanking piercing bending forming forging trimming etc.

Coins metal currency are created with the coining process.

It is a type of bending operation in which a piece of sheet metal is fixed or held between two dies from one end as shown in the fig.

A method of designing a part to be formed from a sheet metal blank is provided according to the following steps.

The global sheet metal market will grow by 69 16 billion from 2018 to 2022 at a 4 compound annual growth rate or cagr.

A simple round metal slug is placed into the die and forced to flow into a given shape by compressing it see figure 3.

Press tools are commonly used in hydraulic pneumatic and mechanical presses to produce the sheet metal components in large volumes.

Final component is obtained after this process.

Additional panels were drawn to failure during both the first draw and the redraw in order to set the parameters for the springback trials and to demonstrate that a sheet metal going through a restrike operation can exceed conventional forming limits of that under a simple draw operation.

This allows for complex shapes to be formed in sheet metal up to 6 mm 0 25 in thick using simple tools.

The press tool will also be specified as a blanking tool piercing tool bending tool etc.

The restrike die operation fundamentally is a solid forming operation.

A final part shape is defined as a computer aided design model.

The first operation blanking prepares the initial approximate shape of the part in flat sheet.

The nibbling process cuts a contour by producing a series of overlapping slits or notches.

Then the other end is forced to strike upon the punch which is free or unfixed.

However normally the operations used extensively are blanking drawing trimming piercing restrike flanging hemming etc.

Notching is a piercing operation that removes material from the edge of the workpiece.

The final shape forming operation can then be performed in a fluid pressure forming tool after the initial drawing operation is completed.

One of the key drivers behind this upward momentum is unprecedented innovation in the machine tools market.

It is expected that the simulation tool is able to model various processes and operations of sheet metal forming one by one or even in combination.

Thus the free or unfixed edge of the sheet metal piece is bent to make the forming process.

Binder closure deep drawing process with draw beads etc stretch forming processes trimming operation flanging operation restrike operations hydroforming process.

The sheet metal forming is the important manufacturing industry as it manufactures chip less products.

Coining also can reduce the metal thickness.

Also eliminates spring back effect.